PE Weld Bank datalogging system

PE Weld Bank mobile app is a powerful QA, risk management and productivity tool that helps you accurately track your poly welding processes in real time.

PE Weld Bank mobile app and data recording system replaces the need for manual paper records..

PE Weld Bank mobile app ensures correct welding parameters are being adhered to by prompting the operator through each fusion welding step, whilst displaying timers, actual pressures and temperatures.

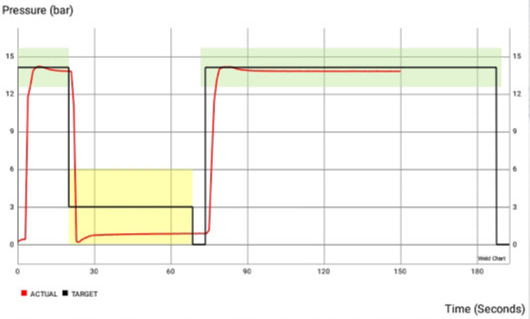

When combined with the Bluetooth sensor device set, PE Weld Bank accurately records the temperatures and welding pressures, allowing instant review of welding results through the interactive onscreen welding graph*.

All weld data is securely uploaded and stored in the online Fusion Management System (FMS) in real time, allowing you to review any weld, track welder and project productivity, and share reports with your clients

For Pressure and Temperature Data Recording, include a Bluetooth Sensor set, to ensure all the critical weld functions are followed correctly

Sensor set includes:

Bluetooth Pressure sensor, inc. ambient and humidity sensors

Pressure Transducer & connection cable

USB charge cable

Bluetooth Temperature sensor

Surface Temperature probe

PT 100 temperature probe connection leads

USB charge cable

Sensors connect via Bluetooth to your smartphone or tablet

Download the Example Weld Report from PE Weld Bank

FHS Poly - Poly Solution ExpertsAustralia and overseas delivery available

Available for HIRE!

Enquire here to contact our team for more information on price and availability.

PE Weld Bank mobile app is a powerful QA, risk management and productivity tool that helps you accurately track your poly welding processes in real time.

PE Weld Bank mobile app and data recording system replaces the need for manual paper records..

PE Weld Bank mobile app ensures correct welding parameters are being adhered to by prompting the operator through each fusion welding step, whilst displaying timers, actual pressures and temperatures.

When combined with the Bluetooth sensor device set, PE Weld Bank accurately records the temperatures and welding pressures, allowing instant review of welding results through the interactive onscreen welding graph*.

All weld data is securely uploaded and stored in the online Fusion Management System (FMS) in real time, allowing you to review any weld, track welder and project productivity, and share reports with your clients

For Pressure and Temperature Data Recording, include a Bluetooth Sensor set, to ensure all the critical weld functions are followed correctly

Sensor set includes:

Bluetooth Pressure sensor, inc. ambient and humidity sensors

Pressure Transducer & connection cable

USB charge cable

Bluetooth Temperature sensor

Surface Temperature probe

PT 100 temperature probe connection leads

USB charge cable

Sensors connect via Bluetooth to your smartphone or tablet

Download the Example Weld Report from PE Weld Bank

FHS Poly - Poly Solution ExpertsAustralia and overseas delivery available

Available for HIRE!

Enquire here to contact our team for more information on price and availability.

PE Weld Bank mobile app is a powerful QA, risk management and productivity tool that helps you accurately track your poly welding processes in real time.

PE Weld Bank mobile app and data recording system replaces the need for manual paper records..

PE Weld Bank mobile app ensures correct welding parameters are being adhered to by prompting the operator through each fusion welding step, whilst displaying timers, actual pressures and temperatures.

When combined with the Bluetooth sensor device set, PE Weld Bank accurately records the temperatures and welding pressures, allowing instant review of welding results through the interactive onscreen welding graph*.

All weld data is securely uploaded and stored in the online Fusion Management System (FMS) in real time, allowing you to review any weld, track welder and project productivity, and share reports with your clients

For Pressure and Temperature Data Recording, include a Bluetooth Sensor set, to ensure all the critical weld functions are followed correctly

Sensor set includes:

Bluetooth Pressure sensor, inc. ambient and humidity sensors

Pressure Transducer & connection cable

USB charge cable

Bluetooth Temperature sensor

Surface Temperature probe

PT 100 temperature probe connection leads

USB charge cable

Sensors connect via Bluetooth to your smartphone or tablet

Download the Example Weld Report from PE Weld Bank

FHS Poly - Poly Solution ExpertsAustralia and overseas delivery available

Available for HIRE!

Enquire here to contact our team for more information on price and availability.

See Below an overview of the PE Weld Bank Reports for Quality Assurance and Tracking purposes